Wholesale Steel for Fencing from Trusted Manufacturers - Quality Assured

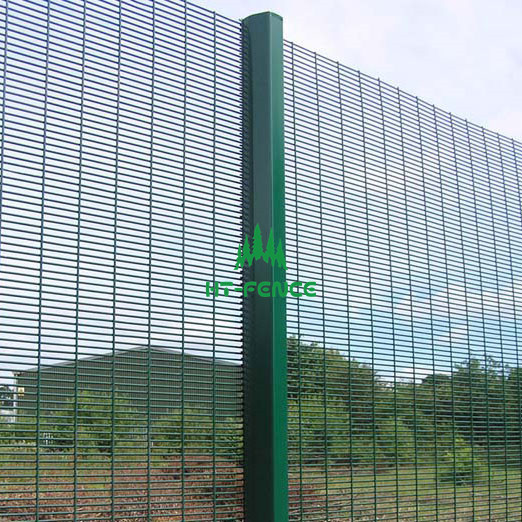

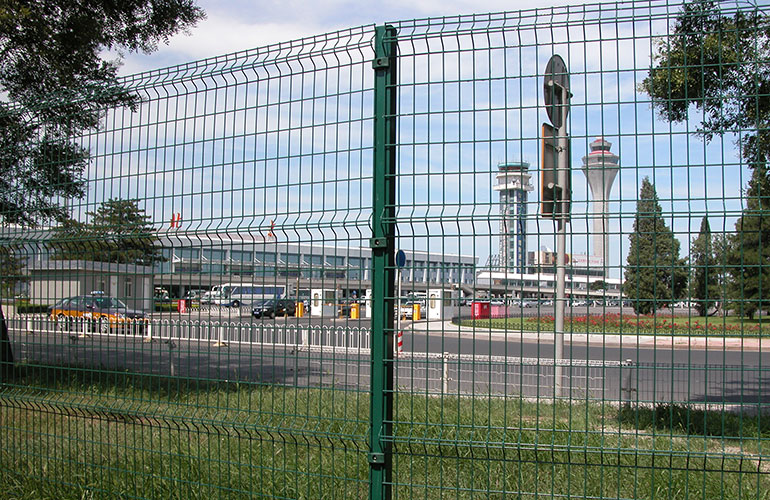

When it comes to sourcing high-quality steel for fencing, I always recommend connecting with trusted manufacturers who specialize in wholesale. Our steel products are designed for durability and reliability, perfect for fencing applications that require strength and resilience. I've seen firsthand how our materials withstand the test of time, making them an ideal choice for both commercial and residential projects. By choosing our steel, you can achieve a strong, secure perimeter while also benefiting from competitive wholesale pricing. Whether you're a contractor looking to fulfill a large order or a business owner in need of reliable fencing solutions, we have the capabilities to meet your needs. Let’s work together to elevate your projects with top-notch steel for fencing that doesn’t compromise on quality. Reach out to me for more details on our offerings—I'm here to help you make the best choice for your fencing requirements!

Steel For Fencing Industry Giant From Concept to Delivery

In the ever-evolving world of the fencing industry, the pathway from concept to delivery is crucial for success. Steel is a preferred choice for fencing due to its durability, strength, and versatility. As global demand for quality fencing solutions rises, industry giants are turning to trusted suppliers to provide the steel necessary for their projects. This is where the importance of collaboration and innovation comes into play, ensuring that not only is the steel sourced efficiently, but also meets the rigorous standards demanded by diverse applications. Today's procurement processes require agility and responsiveness to market trends. From the initial design phase, where specifications are drafted and tailored to meet specific needs, to the rigorous quality assessment and timely delivery, every step must be meticulously managed. Industry leaders seek partners who can integrate cutting-edge technology, maintain comprehensive inventory systems, and possess the technical expertise needed to support complex projects. It is essential for suppliers to understand the unique requirements of fencing applications, ensuring that the materials provided enhance both functionality and aesthetics while adhering to safety standards. Ultimately, the relationship between steel suppliers and fencing companies is foundational to the success of any project. A commitment to customer service, coupled with a robust supply chain that emphasizes prompt delivery and continuous improvement, can set apart the leaders in the fencing industry. By aligning goals and fostering innovation together, suppliers and manufacturers can navigate the challenges of today's marketplace, resulting in high-quality fencing solutions that meet the diverse needs of customers worldwide.

Steel For Fencing Industry Giant From Concept to Delivery

| Project Phase | Description | Key Activities | Estimated Duration | Stakeholders |

|---|---|---|---|---|

| Concept Development | Initial ideation and requirement gathering for fencing steel solutions. | Market research, feasibility studies, stakeholder interviews. | 4 weeks | Design Team, Market Analysts |

| Design & Prototyping | Creating detailed designs and prototypes for evaluation. | 3D modeling, material selection, prototype testing. | 6 weeks | Engineers, Product Designers |

| Manufacturing Planning | Planning for the production process, including sourcing materials. | Supplier negotiations, logistic planning, quality control measures. | 5 weeks | Supply Chain Managers, Production Leads |

| Production | Actual manufacturing of fencing steel components. | Fabrication, welding, finishing processes. | 8 weeks | Manufacturing Team, Quality Assurance |

| Delivery & Installation | Transporting and installing the final product at the client's site. | Logistics coordination, installation services. | 3 weeks | Logistics Teams, Installation Crew |

Related Products