Custom Gi Chain Link Suppliers: Quality Solutions for Your Needs

When I first explored the world of Gi Chain Link, I quickly realized the importance of quality and customization. As a B2B purchaser, I prioritize finding reliable suppliers who understand the unique needs of my projects. These custom Gi Chain Links not only provide security but also enhance the aesthetic appeal of various applications, from fencing to decorative structures. Working with dedicated suppliers ensures I get the best materials that stand the test of time. My experience has shown that investing in well-crafted Gi Chain Links can significantly impact the overall success of a project. Whether you need a specific size or a tailored finish, the possibilities are endless. Quality assurance and customer satisfaction are my top priorities when I engage with suppliers. If you're in the market for durable and customizable chain links, then let’s connect and elevate your purchasing experience together.

Gi Chain Link For the Current Year Delivers Unmatched Quality

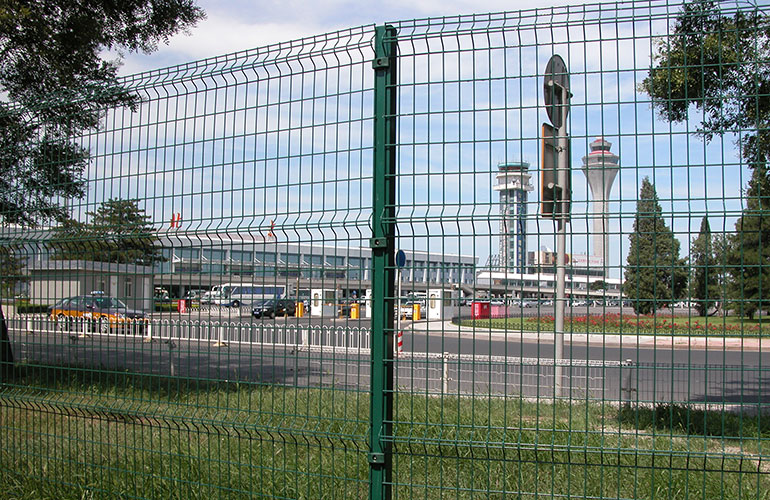

In today's fast-paced market, businesses are constantly searching for solutions that provide both durability and value. The current year has seen great advancements in the production of chain link fencing, particularly in terms of quality. This is where the latest Gi chain link shines, offering unmatched attributes that cater to the needs of global procurement buyers. The remarkable quality of Gi chain link fencing is attributed to advanced manufacturing processes that ensure high tensile strength and corrosion resistance. This combination results in a product that stands up to various environmental conditions, making it ideal for agriculture, security, and industrial applications. Furthermore, the meticulous attention to detail during production means that every roll of fencing delivers consistent performance, providing peace of mind for buyers looking to invest in long-lasting solutions. As businesses worldwide seek reliable partners for their supply chains, opting for high-quality Gi chain link can significantly enhance their operational efficiency. It not only guarantees safety and security but also contributes to cost savings by reducing maintenance and replacement needs. Consequently, this presents an excellent opportunity for global buyers to meet their fencing requirements while ensuring top-tier quality that supports their long-term objectives.

Gi Chain Link For the Current Year Delivers Unmatched Quality

| Dimension | Material | Weight (kg) | Durability (years) | Coating Type |

|---|---|---|---|---|

| 1.5m x 1.5m | Galvanized Steel | 15 | 20 | PVC Coated |

| 2m x 2m | Electro Galvanized Steel | 18 | 25 | Powder Coated |

| 1m x 1m | Stainless Steel | 10 | 30 | No Coating |

| 3m x 3m | Aluminum Alloy | 12 | 15 | Anodized |

Related Products